TL;DR

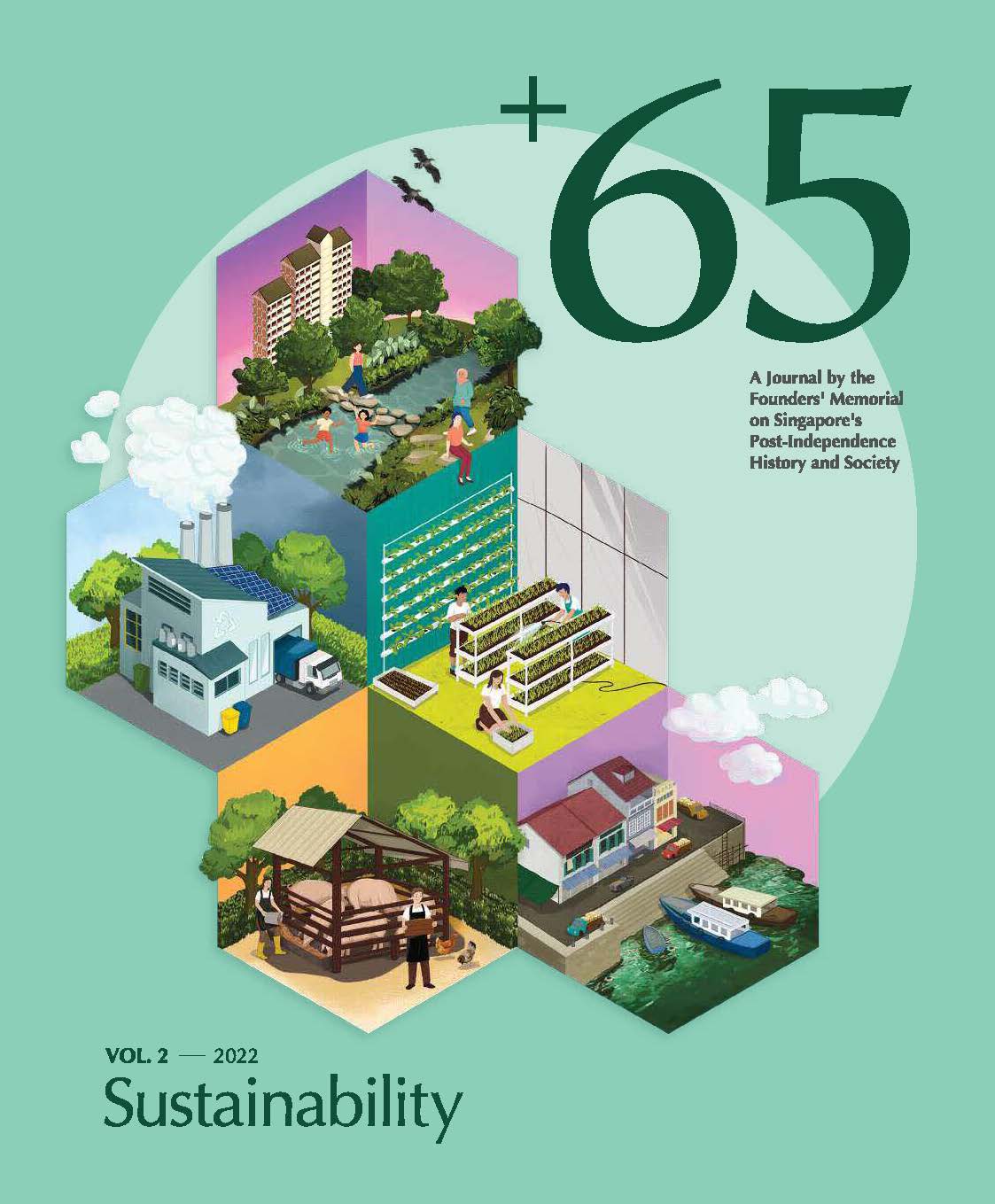

The article traces the growth of Singapore's plastic industry from the late 1940s to the early 1970s. Initially viewed as a catalyst for economic development and improved living, plastic production surged with government support. The industry's expansion brought a variety of products into homes, particularly in kitchens, where plastic was valued for its cleanliness and durability. The article acknowledges the current environmental concerns but underscores the historical significance of plastic in Singapore's industrialization and daily life. This article complements the special international exhibition by the Vitra Design Museum, V&A Dundee, and maat, Lisbon, "Plastic: Remaking Our World" hosted at the National Museum of Singapore, which explores the role of plastic in global design trends from the 1850s till today.When we think about plastic today, what often comes to mind is the problem of plastic waste and various environmental issues related to it. However, plastic was initially not associated with problems, but with possibilities. The immediate period after World War Two saw the exponential rise of plastic production and consumption globally.[1] Plastic was regarded positively, as a growing industry that could contribute to economic development by governments and manufacturers, as well as a product that had the potential to improve consumer’s lives, especially at home. Singapore too became part of these developments, both as a manufacturer and consumer of plastic products. This article traces the initial production and use of plastic goods in Singapore from the late 1940s to the early 1970s.[2]

Small-scale plastic manufacturing began in Singapore very soon after World War Two. One of the first known plastic factories was opened by Yeow Meng Cheow in 1946. It manufactured “display signs, lampshades, table and wall lamps, frames and signboards” made from Perspex imported from England. Before opening the factory, the first plastic object Yeow had made was a mahjong set for his wife. Numerous requests for sets from friends followed, motivating Yeow to eventually start manufacturing plastic products. He sold his car, and with the money, purchased equipment such as an electric circular saw to cut plastic sheets. He commented in a 1948 interview, “I believe that one day Singapore will not only derive its wealth from the fact that this city is a port but also because it will become an industrial centre” – which was exactly what happened in the decades that followed.[3]

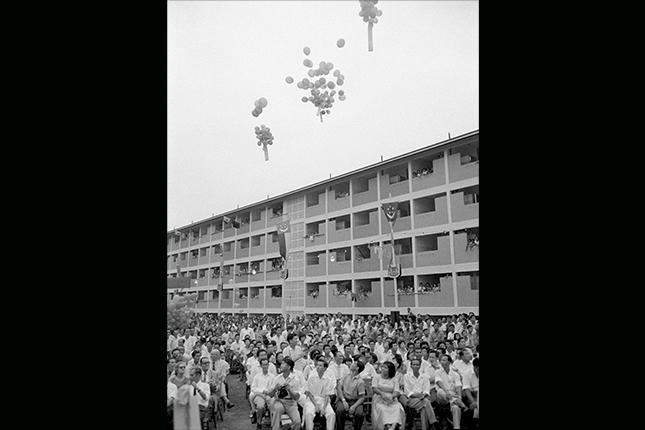

The plastic manufacturing sector in Singapore expanded from the 1950s onwards, alongside a broader shift in focus from trading to manufacturing with an emphasis on industrialisation. Manufacturers tried to keep up with the latest developments in plastic manufacturing by purchasing new machinery and using relatively new materials such as polythene (polyethylene). However, domestic manufacturers faced strong competition from Hong Kong, Japan and United Kingdom imports, prompting these manufacturers to request that the government impose protective tariffs on such goods.[4] In 1962, the government declared that plastic products would be categorised as a pioneer product.[5] This in turn encouraged plastic manufacturers to increase production, as such companies could apply for certificates exempting them from income tax for five years.[6]

The introduction of such measures resulted in a plastic manufacturing boom. By the late 1960s, about five such factories were being established every two months.[7] With greater production of goods, there was also an increase in exports to regional markets including Southeast Asia. In 1969, the Light Industries Services of the Economic Development Board (EDB) described Singapore’s plastics industry as already being in a third stage of development – export-oriented industrialisation – having completed the first two stages of establishment and import substitution in the domestic market.[8]

Parallel to the increase in production was also an expansion in the scale of manufacturing equipment, with more than 1,000 injection machines, compression machines, vacuum forming machines and extruders in operation across 130 factories in 1971.[9] Despite the reliance on machines, a newspaper feature on manufacturer Alliance Plastics emphasised that the role of workers, many of whom were young women, was still key. While a lampshade could be produced by machines every two minutes, human intervention was still needed throughout the process, to feed raw material into the machine, press switches and trim excess plastic.[10] More than the machines themselves, it was the workers’ mastery of the machines and quality checks that ensured superior products.

A wide variety of products were manufactured in Singapore. For example, a display of products from 17 local manufacturers at EDB’s Product and Design Centre at Raffles Place in 1966 included “school bags, shoes, building materials, floor tiles, chairs, pipes, and tube hoses”. The exhibition was part of a series of local product displays which aimed to attract local and foreign buyers as well as showcase the quality of Singapore products to consumers.[11] The catalogue continued to grow – a list of products from 1971 further mentioned “cameras, PVC leather, footwear, packing materials, plastic woven sacks, vinyl tiles, phonograph records, plastic foam, spectacle frames, toys, automobile components, industrial parts, artificial flowers, PVC pipes, hoses and tubings”.[12]

As the plastics industry expanded, many of these products found their way into homes in Singapore. Initially, there was scepticism about plastic as a substitute for materials like glass, wood and metal. Consumers were uncertain whether plastic was a “miracle material” or “third-rate substitute”, especially immediately after the war when there were wide variations in quality of the new plastics being used.[13] Such concerns seem to have reduced by the late 1960s, when a newspaper article described plastic as a superior option, praised for its “efficient, aesthetic, inexpensive and hygienic” qualities, although such views could have been influenced by the ongoing promotion of plastic manufacturing by the government and companies.[14]

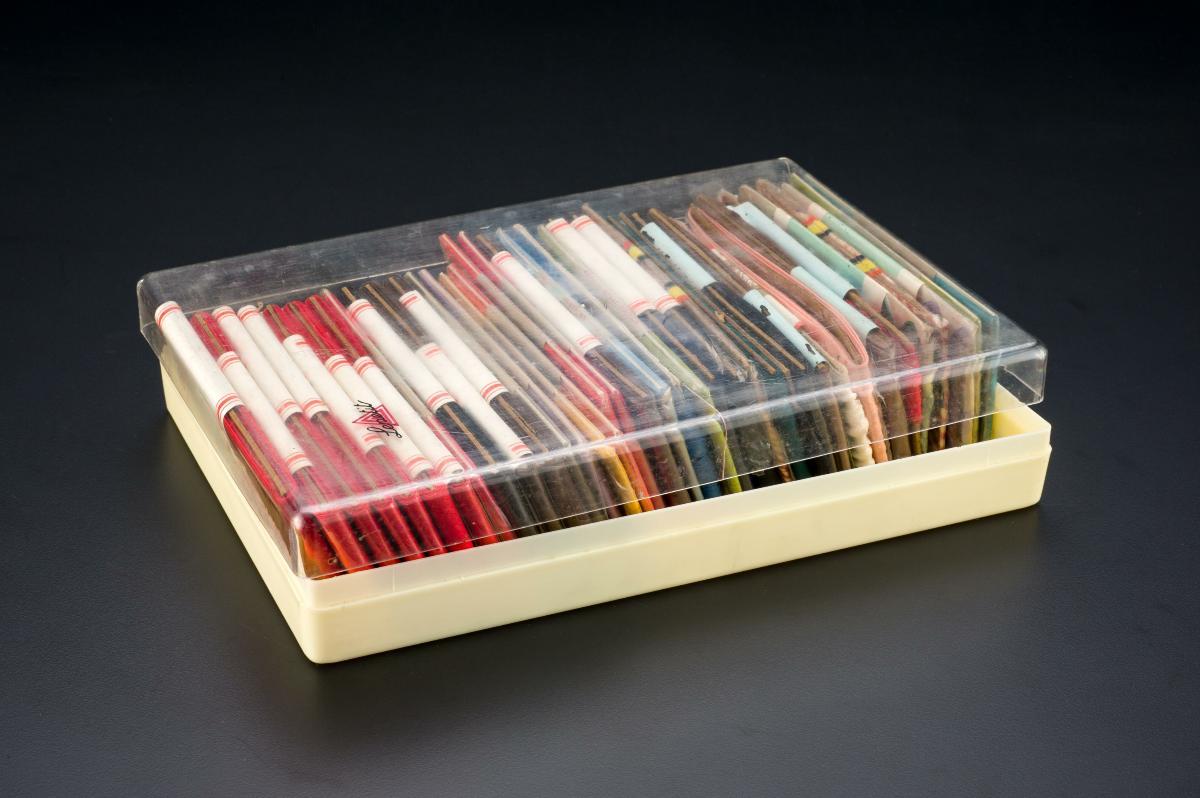

A 1968 Straits Times supplement by a manufacturer, Singa Plastics Limited, similarly celebrated the pervasiveness of plastics. “Plastics have become part of the lives of the people of Singapore. There is not a single moment or a single place in the Republic where people don’t come into contact with plastics. In the morning, when the housewife goes to market, there is a plastic basket on her arm. On the breakfast table there is the plastic tray. At the office and in schools, there are plastic baskets for waste paper”.[15] Though the purpose of the writeup was to advertise how the company produced more than 200 types of plastic goods, it illustrates how consumers had come to use plastic in multiple daily contexts.

Within the home, the kitchen was a key space where consumers adopted plastic products promoted by producers and distributors. The post-war kitchen has been studied as a site of modernity, where women took up new household technologies to manage the home.[16] The modern kitchen was to be hygienic and efficiently run, which plastic supposedly could facilitate since it was easy to clean, durable and affordable. There was therefore strong optimism about plastic and how it could make housework easier by facilitating a wipe-clean world.

The importance of plastic in the kitchen was emphasised in a 1966 television feature by Berita Singapura. A voiceover for a scene with a woman and child in a kitchen commented, “There’s no doubt about it, the invention of plastics has been welcomed by every housewife. Light in weight, easy to keep clean, difficult to break or chip, completely safe for children, and available in gay colours.” To demonstrate the point, the clip showed the woman washing plastic bowls, as well as the child drinking from a plastic cup and throwing it on the floor, without any damage to the cup.[17] Produced as part of efforts to promote the plastics industry, the clip highlights the appeal of plastic products as a solution for women who were managing the home.

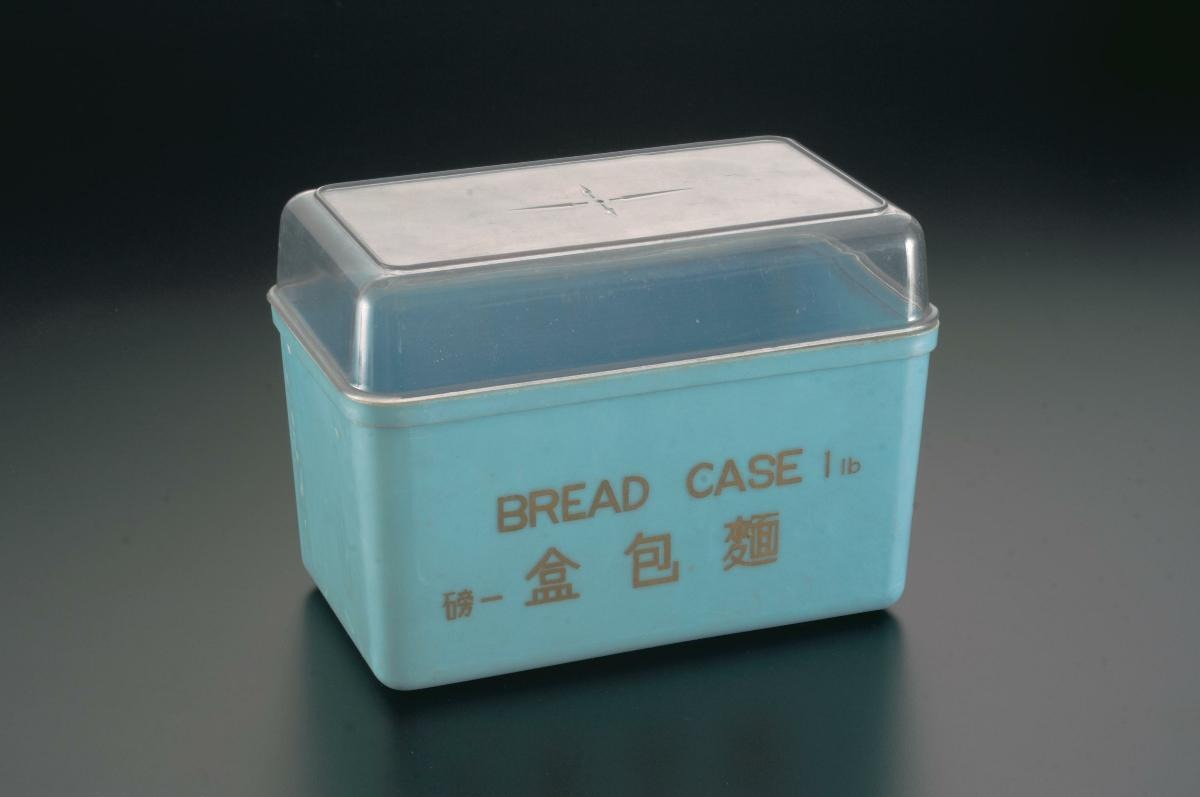

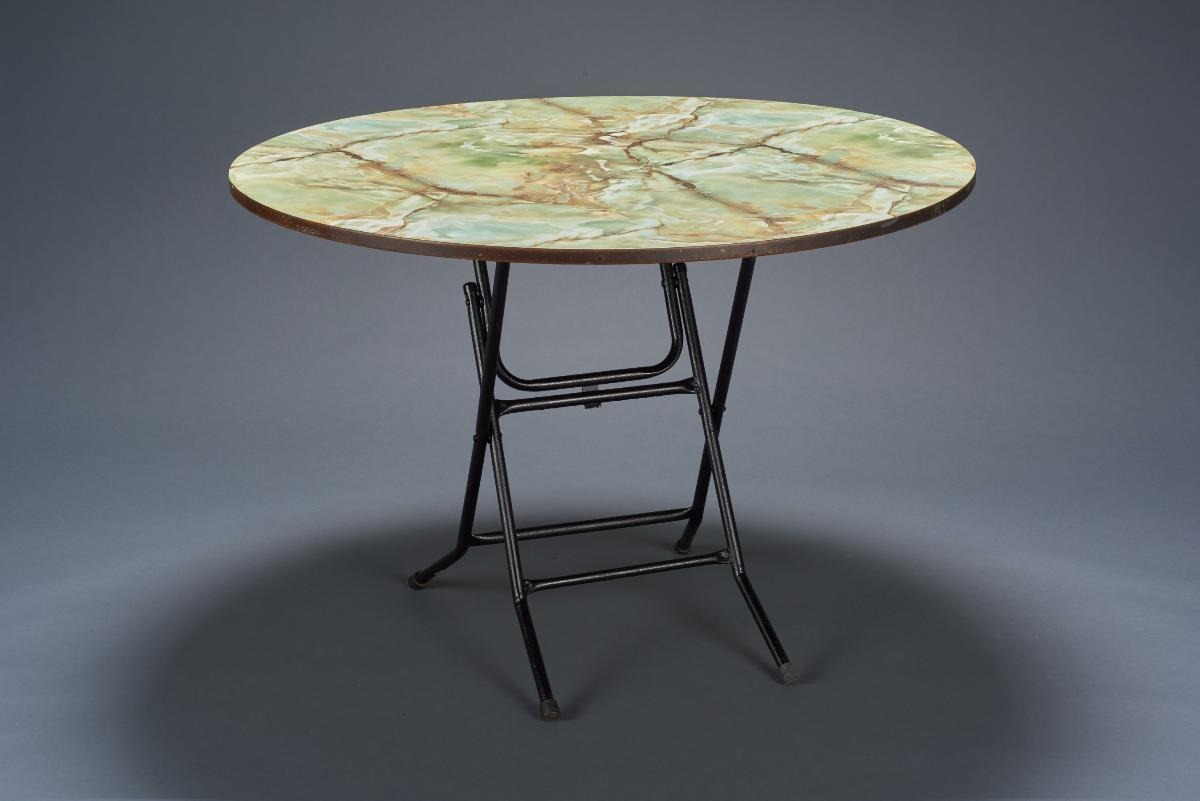

It was during these decades when various plastic products that many in Singapore would recognise or still have in their homes today were introduced. For example, reusable plastic food containers such as Tupperware, which was launched in 1945 and introduced in Singapore in the 1960s, promised to help users save time and money by keeping food fresh for longer, as stated on a Tupperware Singapore booklet from the 1970s to 1980s. Similarly, the plastic laminate formica was commonly used for kitchen surfaces and furniture as it was easy to clean – green formica furniture was a particularly popular choice during the 1950s to 1970s. The enduring impact of plastic on daily life can be seen from these products that became commonly used in homes.

Plastic was initially regarded as a material replete with possibilities in post-war Singapore. From the government and producers’ perspective, the expansion of plastic manufacturing contributed to industrialisation and economic gains. For consumers, it promised a supposedly superior way of living, especially with the entry of plastic products into domestic spaces such as the kitchen. Following the rise of plastic production and usage during the late 1940s to early 1970s, plastic has become a part of our everyday lives. It remains to be seen whether we can relook our relationship with plastic such that it once again offers possibilities rather than problems.

The National Museum of Singapore is presenting the international exhibition Plastic: Remaking Our World from 27 January to 23 June 2024. “Plastics in Singapore”, a digital display of objects from the National Collection which traces the use of plastics locally, can be accessed onsite in the exhibition.

Type of Plastic in Singapore

Notes

- Jeffrey L. Meikle, American Plastic: A Cultural History (New Brunswick, N.J.: Rutgers University Press, 1995), 1-2.

- This is prior to a slowdown in 1973 due to the global shortage of plastic resin, caused by the oil crisis and high demand for the material.

- Roy Ferroa, “Singapore’s Pioneer In Plastics,” The Singapore Free Press, March 1, 1948.

- Geoffrey Boland, “Local plastic trade asks for help,” The Straits Times, February 2, 1960.

- “Plastics industries in Singapore can be multiplied by tenfold,” The Straits Times, December 22, 1961.

- “Pioneer products total now 68,” The Straits Times, February 3, 1962.

- Chen Meng Kong and Yeo Toon Joo, “Big scope for plastics industry expansion,” The Straits Times, October 13, 1968.

- “The new boom in plastics: 30 factories up in a year,” The Straits Times, July 14, 1969,.

- N. G. Kutty, “More factories are set up in Spore to meet increased demand,” The Straits Times, October 3, 1971.

- “1, 2, 3, 4, 5... and out shoots a lampshade,” The Straits Times, April 23, 1967.

- Yeo Toon Joo, “Singapore-made plastic products on display,” The Straits Times, August 11, 1966.

- N. G. Kutty, “More factories are set up in Spore.”

- Meikle, American Plastic, 154.

- Liew Ah Choy, “Many products now packed in pvc bottles,” The Straits Times, April 12, 1970.

- “More than 200 products for the home mart and export,” The Straits Times, November 19, 1968.

- Chan Ying-kit, “Creating Modern Women: The Kitchen in Postcolonial Singapore, 1960–90,” Journal of Southeast Asian Studies 51, no. 3 (September 2020): 416–417. See also Ruth Oldenziel and Karin Zachmann, eds., Cold War kitchen: Americanization, technology, and European users (Cambridge, MA: MIT Press, 2009).

- Berita Singapura, “Singapore plastics,” video, 01:55, 1966.