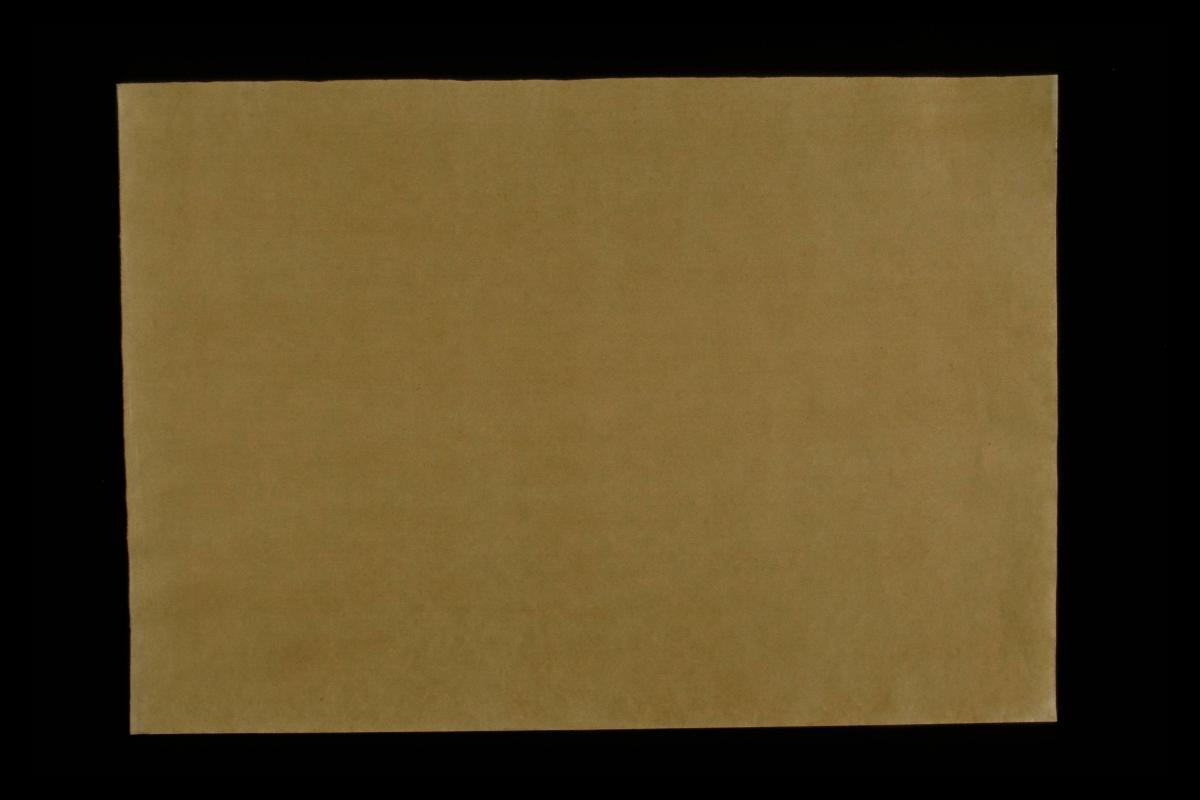

Before a calligrapher begins writing, a paper such as this one is tinted, sealed and polished. Sealing the paper enables corrections to be made without damaging it while polishing gives a smoother surface, which allows the calligrapher to glide the pen along more easily to leave behind a flawless trail of ink. The paper is tinted slightly as white paper can be hard on the eyes. One of the most popular methods of tinting uses tea. Tinting also occurs before sealing otherwise the natural colours will show through when corrections are made. Once the paper is tinted and dried, it is ready for sealing or sizing. In this example, whites of duck eggs and pieces of ‘alum’ (double sulphate of aluminium and potassium) are used to make the sealant. The number of coats depends on the paper and the use. The dried, sealed paper is then straightened on a curved wooden platform to be polished. Polishing smoothens out any rough spots on the paper and helps to fix the size.